DIY Calibration Tips: When to Call in the Experts

Understanding Calibration: A Basic Overview

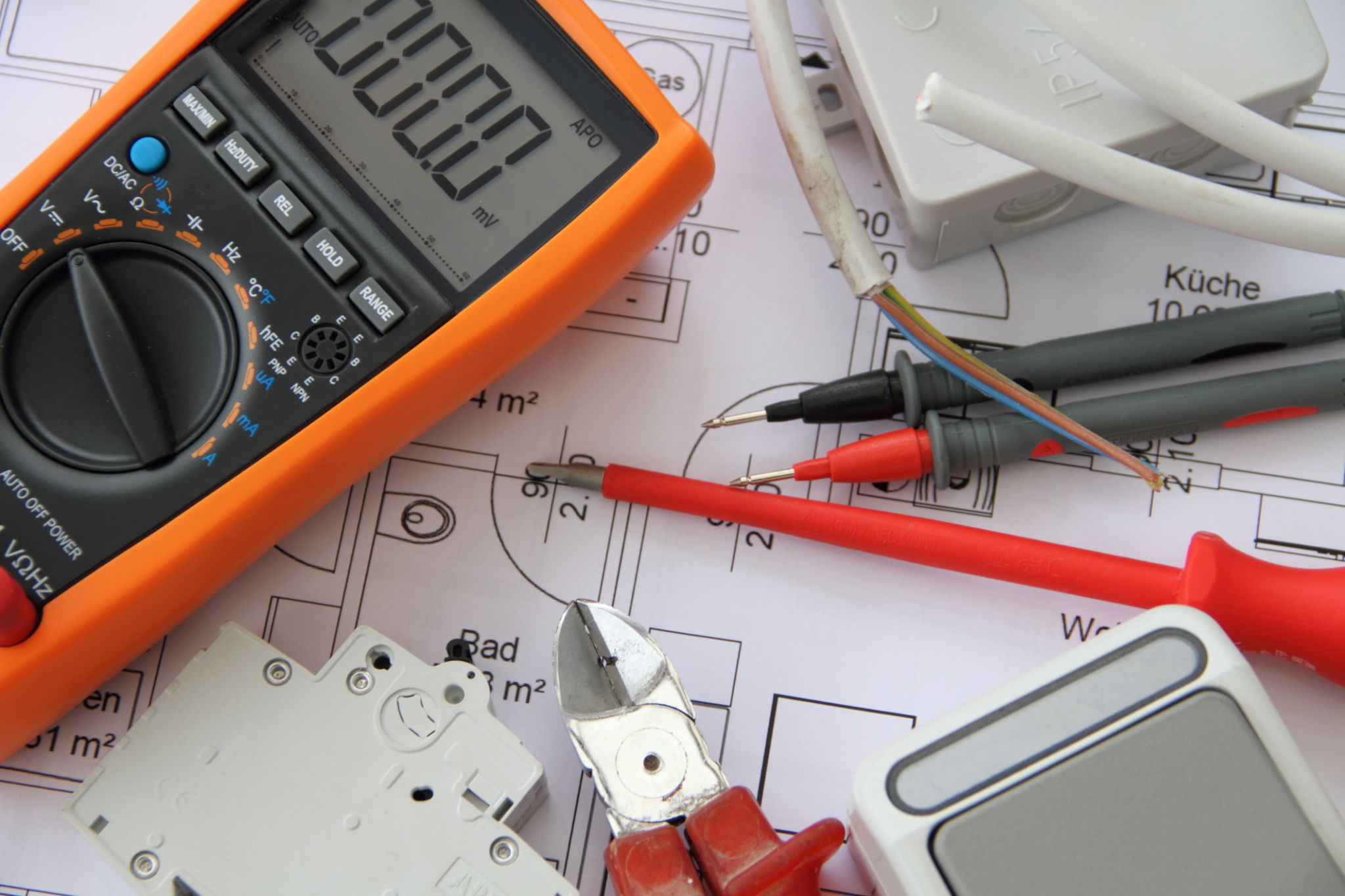

Calibration is an essential process across various industries to ensure that instruments and equipment provide accurate and precise measurements. Maintaining proper calibration helps in achieving consistent product quality and operational efficiency. For those who prefer a hands-on approach, some DIY calibration techniques can be employed, but knowing when to call in the experts is crucial.

DIY calibration can be a cost-effective solution for individuals or small businesses. However, it's important to understand the limitations of DIY approaches to avoid potential pitfalls that may lead to inaccurate results. In this post, we will explore some DIY calibration tips and highlight when it’s best to seek professional assistance.

DIY Calibration Tips

Start with a Clean Workspace

Before beginning any calibration process, ensure your workspace is clean and free from any contaminants that could affect measurement accuracy. Dust, moisture, and other particles can interfere with sensitive equipment, leading to skewed results. Regular cleaning of both the equipment and the surrounding area is a simple yet effective way to maintain accuracy.

Use Reference Standards

Reference standards are a cornerstone of effective calibration. These are devices or materials with known properties against which your instruments can be compared. It is critical to use high-quality reference standards that are traceable to national or international standards. This ensures that your calibration efforts align with global benchmarks, providing confidence in your measurements.

Document Your Process

Documentation is an often overlooked but vital part of the calibration process. Keeping detailed records of each calibration session, including the methods used, reference standards employed, and results obtained, can help track performance over time. This documentation serves as a valuable resource for troubleshooting and future calibrations.

When to Call in the Experts

Complex Equipment

While DIY methods can be effective for simple instruments, complex equipment may require expert attention. If your equipment involves intricate electronics or specialized components that you are not familiar with, it’s wise to consult professionals who have the necessary expertise and tools.

Regulatory Compliance

Industries governed by strict regulatory standards often require professional calibration services to meet compliance requirements. If your business operates within such an industry, relying on experts ensures that you adhere to all necessary guidelines and avoid potential penalties or operational disruptions.

Inconsistent Results

If you notice inconsistent results despite repeated DIY calibration attempts, it may indicate underlying issues that need professional evaluation. Experts can provide a thorough analysis to identify and rectify problems that might not be apparent through basic DIY methods.

Conclusion

While DIY calibration offers a hands-on approach to maintaining equipment accuracy, knowing when to call in the experts is just as important. By understanding the limitations of DIY methods and recognizing situations that require professional intervention, you can ensure that your instruments remain precise and reliable, safeguarding both quality and compliance in your operations.